电话:

86 400-863-2919

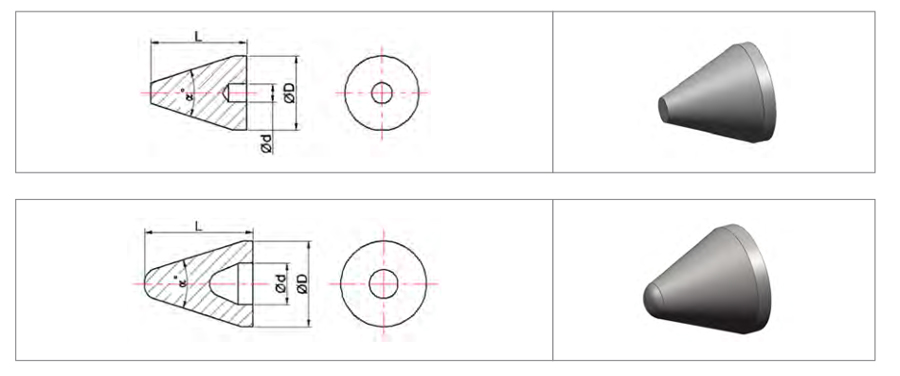

CYC的阀用硬质合金耐磨件因其硬度高、耐磨性、耐腐蚀性、抗冲蚀和抗压及抗震性能好,可满足恶劣工况下的硬面密封需求。

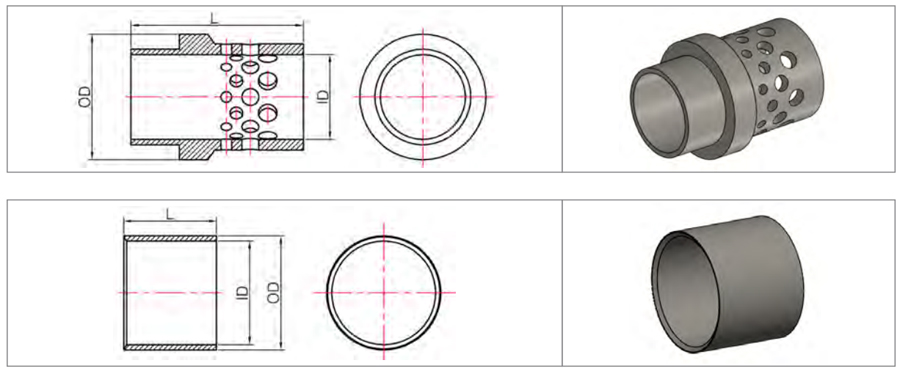

| 尺寸 | 阀芯 | 环 | ||||

| 外径 (mm) | ID(mm) | L(mm) | 外径 (mm) | ID(mm) | L(mm) | |

| 1" | 48.05 | 25.4 | 108.43 | 41.35 | 35.35 | 33.46 |

| 1.5 | 67.32 | 38.1 | 125.45 | 57.27 | 51.11 | 55.8 |

| 2" | 76.19 | 50.8 | 134.58 | 69.9 | 63.98 | 63.09 |

| 3" | 112.93 | 76.2 | 154.66 | 105.02 | 95.58 | 85.3 |

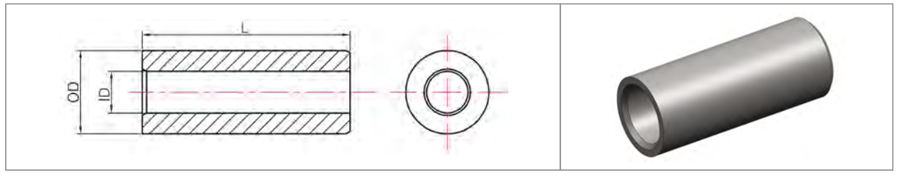

| 尺寸 | 外径 (英寸) | ID(mm) | lD (英寸) | lD(mm) | L (inch) | L(mm) |

| 2/64" | 0.65 | 16.51 | 0.031 | 0.787 | 5.880 | 149.352 |

| 4/64" | 0.062 | 1.575 | ||||

| 6/64" | 0.093 | 2.362 | ||||

| 8/64" | 0.125 | 3.175 | ||||

| 10/64" | 0.65 | 16.51 | 0.156 | 3.962 | ||

| 12/64" | 0.187 | 4.750 | ||||

| 14/64" | 0.218 | 5.537 | ||||

| 16/64" | 0.250 | 6.350 | ||||

| 18/64" | 0.945 | 24.003 | 0.281 | 7.137 | ||

| 20/64" | 0.312 | 7.925 | ||||

| 22/64" | 0.343 | 8.712 | ||||

| 24/64" | 0.375 | 9.525 | ||||

| 26/64" | 0.945 | 24.003 | 0.406 | 10.312 | ||

| 28/64" | 0.437 | 11.100 | ||||

| 30/64" | 0.468 | 11 .887 | ||||

| 32/64" | 0.500 | 12.700 | ||||

| 34/64" | 1.181 | 29.998 | 0.531 | 13.487 | ||

| 36/64" | 0.562 | 14.275 | ||||

| 38/64" | 0.593 | 15.062 | ||||

| 40/64" | 0.625 | 15.875 | ||||

| 42/64" | 1.181 | 29.998 | 0.656 | 16.662 | ||

| 44/64" | 0.687 | 17.450 | ||||

| 46/64" | 0.718 | 18.237 | ||||

| 48/64" | 0.750 | 19.050 | ||||

| 50/64" | 1.339 | 34.011 | 0.781 | 19.837 | ||

| 52/64" | 0.812 | 20.625 | ||||

| 54/64" | 0.843 | 21.412 | ||||

| 56/64" | 0.875 | 22.225 | ||||

| 58/64" | 1.417 | 35.992 | 0.906 | 23.012 | ||

| 60/64" | 0.937 | 23.800 | ||||

| 62/64" | 0.968 | 24.587 | ||||

| 64/64" | 1.000 | 25.400 | ||||

| 66/64" | 1.625 | 41.275 | 1.031 | 26.187 | ||

| 68/64" | 1.062 | 26.975 | ||||

| 70/64" | 1.093 | 27.762 | ||||

| 72/64" | 1.125 | 28.575 | ||||

| 74/64" | 1.156 | 29.362 | ||||

| 76/64" | 1.187 | 30.150 | ||||

| 78/64" | 1.218 | 30.940 | ||||

| 80/64" | 1.772 | 45.009 | 1.250 | 31.750 | ||

| 82/64" | 1.281 | 32.537 | ||||

| 84/64" | 1.312 | 33.325 | ||||

| 86/64" | 1.343 | 34.112 | ||||

| 88/64" | 1.909 | 48.489 | 1.375 | 34.925 | ||

| 90/64" | 1.406 | 35.712 | ||||

| 92/64" | 1.437 | 36.500 | ||||

| 94/64" | 1.468 | 37.287 | ||||

| 96/64" | 2.047 | 51.994 | 38.100 | |||

| 98/64" | 1.531 | 38.887 | ||||

| 100/64" | 1.562 | 39.675 | ||||

| 102/64" | 1.563 | 39.700 | ||||

| 104/64" | 2.165 | 54.991 | 1.625 | 41.275 | ||

| 106/64" | 1.656 | 42.062 | ||||

| 108/64" | 1.687 | 42.850 | ||||

| 110/64" | 1.718 | 43.637 | ||||

| 112/64" | 2.283 | 57.988 | 1.750 | 44.450 | ||

| 114/64" | 1.781 | 45.237 | ||||

| 116/64" | 1.812 | 46.025 | ||||

| 118/64" | 1.843 | 46.812 | ||||

| 120/64" | 2.913 | 73.9902 | 1.875 | 47.625 | ||

| 124/64" | 1.937 | 49.200 | ||||

| 126/64" | 1.968 | 49.987 | ||||

| 128/64" | 2.000 | 50.800 | ||||

| 136/64" | 3.405 | 86.487 | 2.125 | 53.975 | ||

| 144/64" | 2.250 | 57.150 | ||||

| 152/64" | 2.375 | 60.325 | ||||

| 160/64" | 2.500 | 63.500 | ||||

| 168/64" | 2.402 | 61.0108 | 2.625 | 66.675 | ||

| 176/64" | 2.750 | 69.850 | ||||

| 184/64" | 2.875 | 73.025 | ||||

| 192/64" | 3.000 | 76.200 |

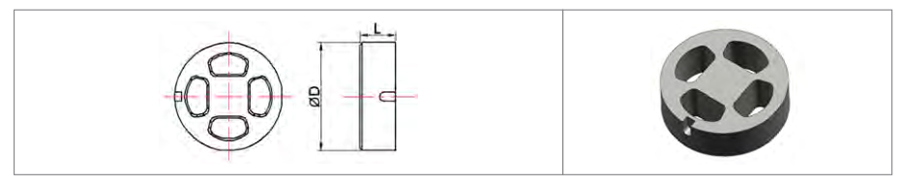

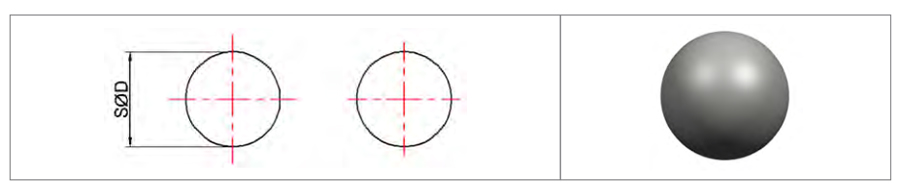

| 球阀芯 | 外径ΦD (inch) | 外径 ΦD (mm) |

| V11-106 | 5/8 | 15.875 |

| V11-125 | 3/4 | 19.05 |

| V11-150 | 15/16 | 23.8125 |

| V11-175 | 1-1/8 | 28.575 |

| V11-225 | 1-3/8 | 34.925 |

| V11-250 | 1-11/16 | 42.8625 |

| V11-375 | 2-1/4 | 57.15 |

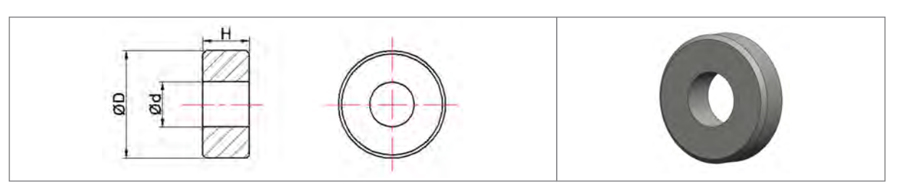

| API席位 | 外径 ΦD (inch) | lD(mm) | lD (inch) | ID(mm) | L (inch) | L(mm) |

| V11-106 | 0.793 | 20.142 | 0.468 | 11.89 | 0.5 | 12.7 |

| V11-125 | 0.918 | 23.317 | 0.575 | 14.61 | 0.5 | 12.7 |

| V11-150 | 1.168 | 29.667 | 0.702 | 17.83 | 0.5 | 12.7 |

| V11-175 | 1.388 | 35.255 | 0.830 | 21.08 | 0.5 | 12.7 |

| V11-225 | 1.720 | 43.688 | 1.046 | 26.57 | 0.5 | 12.7 |

| V11-250 | 2.010 | 51.054 | 1.265 | 32.13 | 0.5 | 12.7 |

| V11-375 | 3.072 | 78.029 | 1.752 | 44.5 | 0.75 | 19.05 |

您的成功始于点击: 立即联系我们!